Did you know that companies using Just-in-Time (JIT) inventory management can reduce storage costs by up to 30%? In today’s fast-paced consumer market, businesses that rely on outdated inventory methods often struggle with inefficiencies, waste, and lost profits. JIT transforms this approach by focusing on real-time demand and precision, ensuring inventory is stocked only when needed.

"In the business world, the rearview mirror is always clearer than the windshield."

– Warren Buffett

Just as Buffett’s quote suggests, businesses that rely too much on hindsight often miss out on opportunities. With JIT, FMCG brands can stay ahead of demand rather than reacting to past trends. This not only optimizes operations but also minimizes financial and operational risks.

What is Just-in-Time (JIT) Strategy?

JIT is an inventory management approach where products are stocked, manufactured, or supplied only when required, reducing excess inventory and associated costs. Unlike the Just-in-Case (JIC) approach, where businesses stockpile goods to avoid shortages, JIT ensures lean inventory levels and replenishment on demand.

For FMCG companies, this means fresh products, reduced waste, and improved cash flow. However, for JIT to work efficiently, companies need precise demand forecasting powered by AI-Powered Sales Force Automation software to anticipate needs and avoid costly stockouts.

How JIT Works in FMCG

JIT in FMCG ensures businesses don’t get caught off guard by unpredictable demand shifts. The process relies on:

1. Demand-Driven Replenishment

Stocking based on real-time sales data and market trends.

2. Technology Integration

AI-powered forecasting and Sales Force Automation (SFA) tools optimize demand prediction.

3. Strong Supplier Relationships

Ensuring just-in-time deliveries through strategic partnerships.

4. Efficient Logistics

Optimized distribution networks for seamless restocking.

Retailers like supermarkets depend on JIT to keep shelves stocked without overloading storage spaces, ensuring fresh goods are always available while minimizing waste.

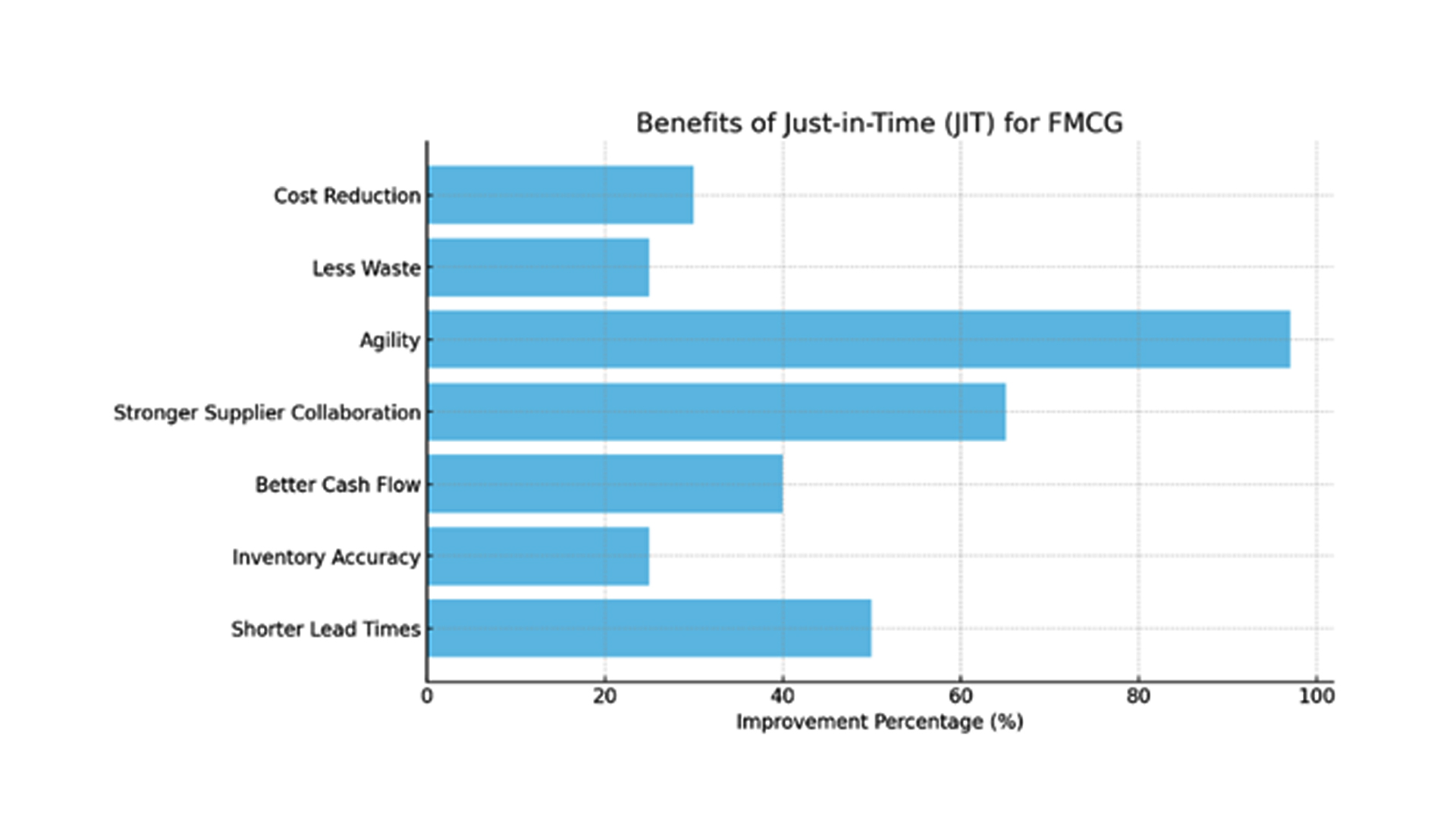

Benefits of JIT for FMCG

1. Cost Reduction

Up to 30% lower storage and holding costs.

2. Less Waste

Significant reduction in overproduction and excess stock, especially for perishable goods.

3. Agility

Up to 97% reduction in cycle times, improving responsiveness to market trends.

4. Stronger Supplier Collaboration

Reduction in suppliers by up to 65%, streamlining operations.

5. Better Cash Flow

Frees up to 40% of space requirements, improving capital allocation.

6. Inventory Accuracy

Companies using JIT improve inventory accuracy by 20-30%, reducing mismanagement.

7. Shorter Lead Times

JIT can cut lead times by up to 50%, ensuring faster order fulfillment.

Challenges of JIT in FMCG

1. Supply Chain Risks

Delays or disruptions can cause stockouts.

2. High Dependence on Suppliers

Reliable partnerships are essential.

3. Accurate Forecasting Required

Miscalculations lead to shortages.

4. Limited Buffer Stock

No room for unexpected demand spikes.

During the pandemic, many FMCG brands faced shortages due to supply chain breakdowns. However, businesses with AI-driven forecasting software navigated these disruptions more effectively, using real-time demand predictions and automated inventory adjustments to maintain stability.

Implementing JIT Successfully

1. Use AI-Powered Automation

Tools like SalesJump optimize demand tracking, ensuring precise forecasting.

2. Diversify Suppliers

Reduces risks of disruptions.

3. Optimize Logistics

Fast, reliable transportation prevents stockouts.

4. Monitor Consumer Trends

Staying ahead of shifts in demand is crucial.

Real-World Examples

McDonald's

Uses JIT for fresh food preparation, minimizing waste.

Procter & Gamble (P&G)

Leverages predictive analytics for efficient restocking.

Zara

Though not FMCG, its JIT-inspired retail model reduces unsold inventory.

Beyond JIT: Leveraging AI for Maximum Supply Chain Efficiency

Buffett’s insight reminds us that looking ahead is more valuable than dwelling on past data. In today’s competitive FMCG landscape, JIT can drive profitability, but only when supported by accurate forecasting, strong supplier collaboration, and real-time inventory insights.

This is where SalesJump makes all the difference. By integrating AI-driven forecasting, automated stock replenishment, and real-time analytics, SalesJump ensures businesses stay ahead of demand fluctuations. Companies leveraging SalesJump’s automation software can minimize stockouts, reduce excess inventory, and maximize profitability—turning JIT from a risk into a competitive advantage.

Ready to future-proof your inventory strategy?

Try the SalesJump demo today!